Bilaspur News

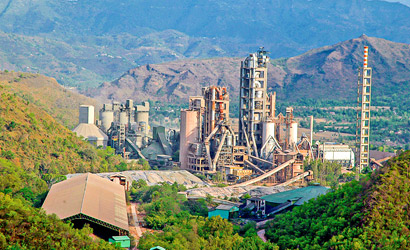

NGT Panel Uncovers Major Lapses at ACC Cement Plant in Himachal Pradesh After Air Pollution Complaint

Earlier, the Himachal Pradesh Pollution Control Board Fined ACC Cement Plant Rs 1.29 Crore for Violations

Complainant Raises Suspicion Over Plant’s Environmental Practices

When reached for comment, Thakur expressed skepticism about the timing of the plant’s maintenance shutdown, which occurred just days before the joint committee’s inspection. He stated, “We suspect that the authorities are just delaying the process. We are requesting an inspection by independent experts, and we will reiterate this demand at the next hearing on February 25.”